Overview

OEE-Controller based MDI

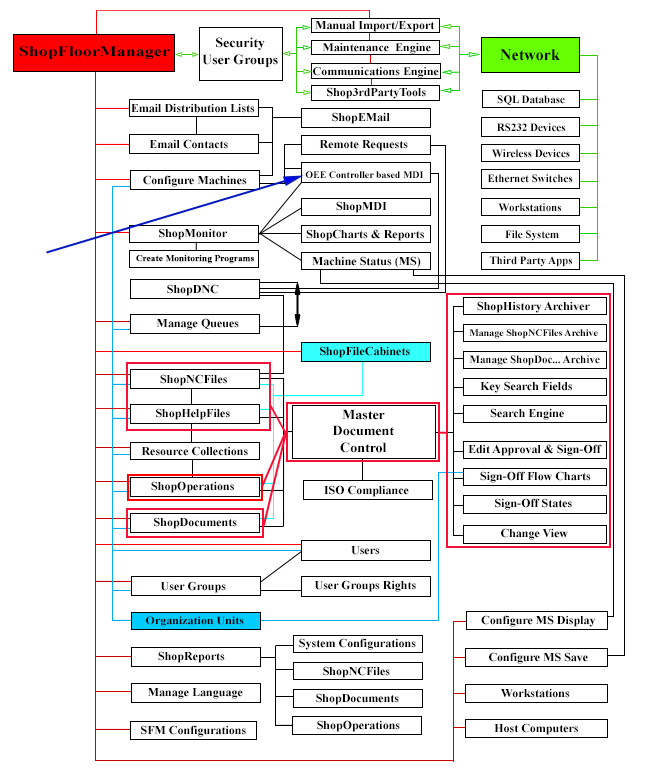

OEE-Controller based MDI (Part of ShopFloorManager's Integrated Architecture)

ShopFloorManager Architecture

OEE-Controller based MDI is fully integrated into ShopFloorManager's Architecture inheriting the intrinsic:

foundational features, security, intra-operability, look and feel, internal data exchange and

document control mechanisms as does the rest of ShopFloorManager's Applications!

OEE-Controller based MDI's Place in the Architecture

Note: Interrogate the Graphic above to investigate the various Application's Intra-Relationships by clicking on the Rectangles.

ShopFloorMonitoring OEE-Controller-based-MDI RRC Templates

The Event RRC Template Set, OEE-Breakdowns Events, is a complete set (customer defined) of possible OEE Events for this OEE Category.

These RRC Templates are automatically generated from the associated customer created monitoring programs during the downloading process. These RRC Templates are generated

by a direct Mapping of the Events in the OEE based Monitoring Programs to the Controller Formatted RRC Templates during the Queuing & Downloading Process.

This means anytime an OEE Monitoring Program is created or modified it is immediately reflected in the Mapping Process. This Automated Process is possible because of the fully

integrated design of ShopFloorManager.

OEE RRC Templates Generation

OEE RRC Automatic Generation

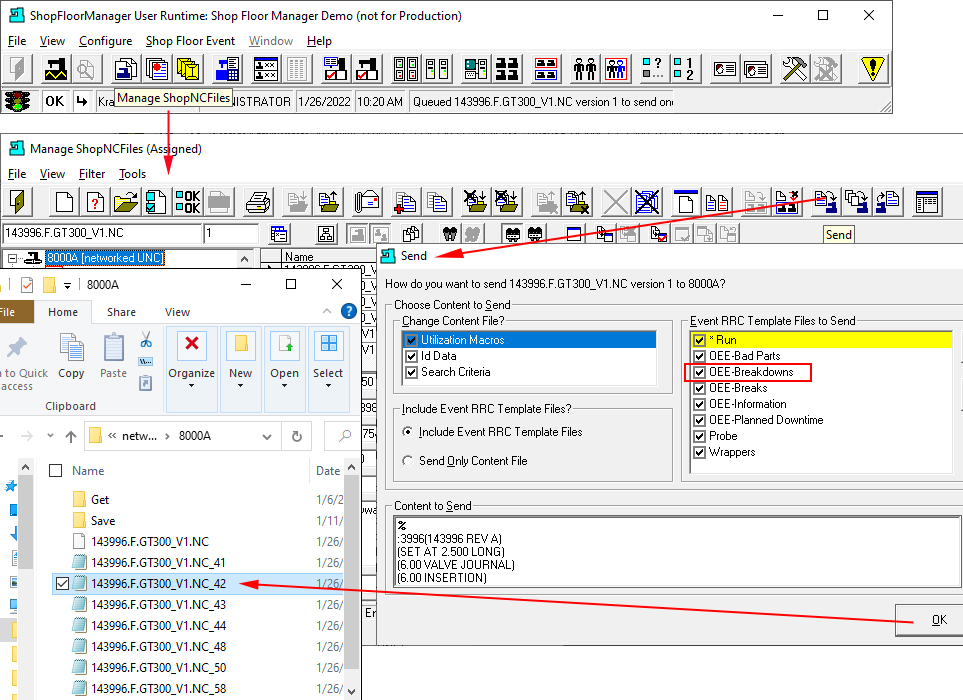

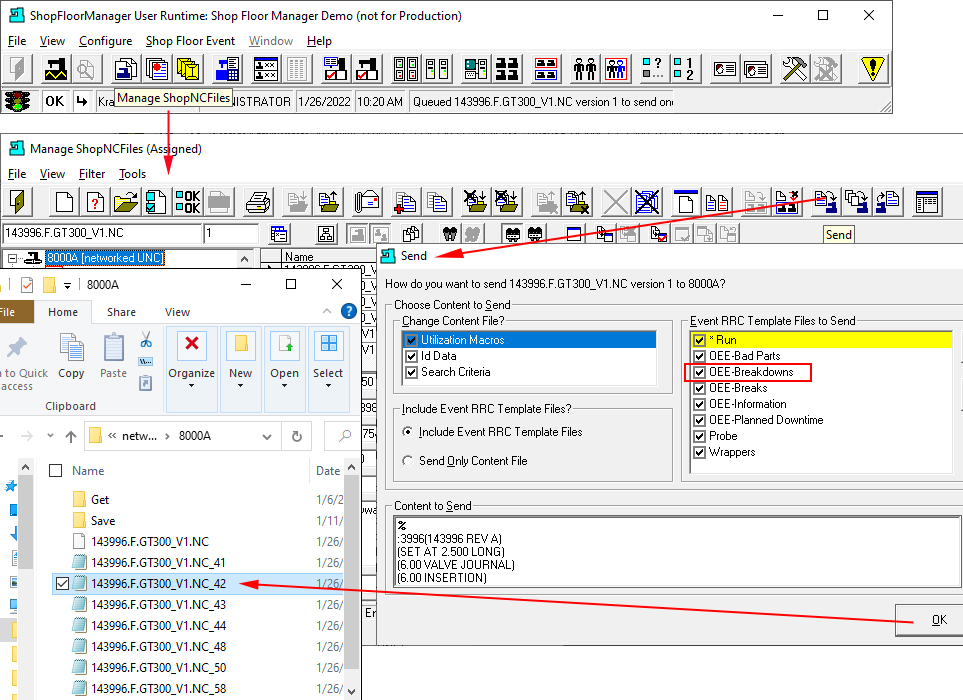

Queuing RRC Templates (Part of ShopFloorManager's Integrated Architecture)

RRC Templates

Note: Interrogate the Graphic above to investigate the Queuing and Downloading Process.

If you follow the Red Arrows you can see the complete Queuing Process from selecting a ShopNCFile to downloading the ShopNCFile and the selected

RCC Templates(Monitoring Programs)! This is a quick visual of the process.

Note: You can find more details describing the Queuing Process in other Sub-Websites and our User Manual.

The list of generated RRC Templates. OEE Category: ShopNCFile Name

- Run: 43996F.GT300.V1.NC

- This is the Normal ShopNCFile

- OEE-Bad Parts: 143996F.GT300.V1.NC_41

- This is the Associated RRC Template Monitoring File

- OEE-Breakdowns: 143996F.GT300.V1.NC_42

- This is the Associated RRC Template Monitoring File

- OEE-Breaks: 143996F.GT300.V1.NC_43

- This is the Associated RRC Template Monitoring File

- OEE-Information: 143996F.GT300.V1.NC_44

- This is the Associated RRC Template Monitoring File

- OEE-Planned Downtime: 143996F.GT300.V1.NC_48

- This is the Associated RRC Template Monitoring File

- OEE Probe: 143996F.GT300.V1.NC_50

- This is the Associated RRC Template Monitoring File

- OEE Wrappers: 143996F.GT300.V1.NC_58

- This is the Associated RRC Template Monitoring File

You will notice that "Controller Name" in this example is O4103(See below) and is guaranteed to be unique among RRC Templates. ShopFloorMonitoring allows a User to define the initial string of

characters that are compatible with each Controller's format while ShopFloorMonitoring adds the last two characters (numbers).

This N/C File uses the Fanuc type naming convention but any type can be created using ShopFloorMonitoring!

The User should define the first set of characters of the name to be in a "range" that is set aside for RRC Templates to avoid ShopNCFile Naming conflicts!

Notes:

- This automated creation methodology is possible because of ShopFloorManager’s fully Integrated System vs the Addon after-thought Approach used by our competitors!

- This automatic Mapping of the Monitoring Program Events to the RRC Templates during downloading guarantees the most up to date RRC Template Files while replacing the old RRC Templates in

the Controller!

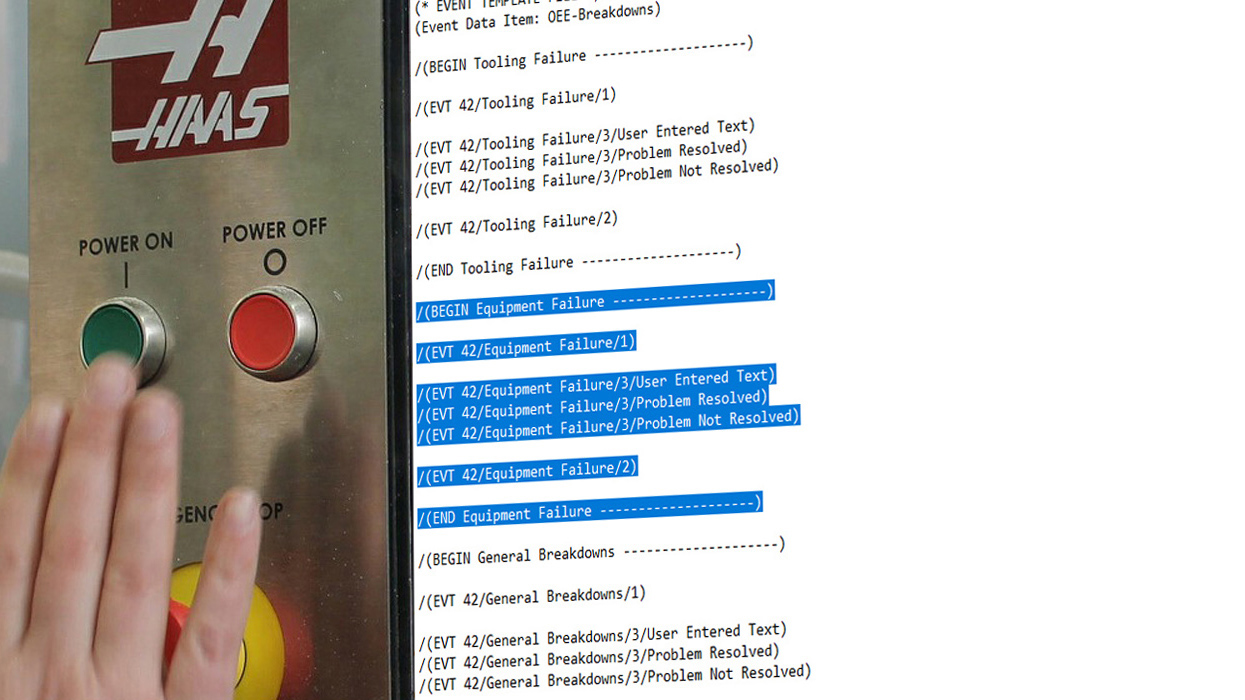

Complete Set of OEE-Breakdowns(Monitoring File:143996F.GT300.V1.NC_42) "Events"

These "OEE-Controller-bases-MDI" RRC Templates are used to accomplish the same outcome as when using ShopFloorMDI to enter the OEE Data and doesn't require the use of Scanners, associated

hardware, software and the added paper work clutter!

Note: You can find more information about ShopFloorMDI in the other Sub-Websites and our User Manual!

%

O4103

(* EVENT TEMPLATE FILE *)

(Event Data Item: OEE-Breakdowns)

/(BEGIN Tooling Failure --------------------)

/(EVT 42/Tooling Failure/1)

/(EVT 42/Tooling Failure/3/User Entered Text)

/(EVT 42/Tooling Failure/3/Problem Resolved)

/(EVT 42/Tooling Failure/3/Problem Not Resolved)

/(EVT 42/Tooling Failure/2)

/(END Tooling Failure --------------------)

/(BEGIN Equipment Failure --------------------)

/(EVT 42/Equipment Failure/1)

/(EVT 42/Equipment Failure/3/User Entered Text)

/(EVT 42/Equipment Failure/3/Problem Resolved)

/(EVT 42/Equipment Failure/3/Problem Not Resolved)

/(EVT 42/Equipment Failure/2)

/(END Equipment Failure --------------------)

/(BEGIN General Breakdowns --------------------)

/(EVT 42/General Breakdowns/1)

/(EVT 42/General Breakdowns/3/User Entered Text)

/(EVT 42/General Breakdowns/3/Problem Resolved)

/(EVT 42/General Breakdowns/3/Problem Not Resolved)

/(EVT 42/General Breakdowns/2)

/(END General Breakdowns --------------------)

/(BEGIN Medical --------------------)

/(EVT 42/Medical/1)

/(EVT 42/Medical/3/User Entered Text)

/(EVT 42/Medical/3/Problem Resolved)

/(EVT 42/Medical/3/Problem Not Resolved)

/(EVT 42/Medical/2)

/(END Medical --------------------)

/(BEGIN Unplanned Maintenance --------------------)

/(EVT 42/Unplanned Maintenance/1)

/(EVT 42/Unplanned Maintenance/3/User Entered Text)

/(EVT 42/Unplanned Maintenance/3/Problem Resolved)

/(EVT 42/Unplanned Maintenance/3/Problem Not Resolved)

/(EVT 42/Unplanned Maintenance/2)

/(END Unplanned Maintenance --------------------)

/(BEGIN Personnel Relief --------------------)

/(EVT 42/Personnel Relief/1)

/(EVT 42/Personnel Relief/3/User Entered Text)

/(EVT 42/Personnel Relief/3/Problem Resolved)

/(EVT 42/Personnel Relief/3/Problem Not Resolved)

/(EVT 42/Personnel Relief/2)

/(END Personnel Relief --------------------)

Continued from Column 1

/(BEGIN

Component Jams --------------------)

/(EVT 42/

Component Jams/1)

/(EVT 42/

Component Jams/3/

User Entered Text)

/(EVT 42/

Component Jams/3/Problem Resolved)

/(EVT 42/

Component Jams/3/Problem Not Resolved)

/(EVT 42/

Component Jams/2)

/(END

Component Jams --------------------)

/(BEGIN

Delivery Blocked --------------------)

/(EVT 42/

Delivery Blocked/1)

/(EVT 42/

Delivery Blocked/3/

User Entered Text)

/(EVT 42/

Delivery Blocked/3/Problem Resolved)

/(EVT 42/

Delivery Blocked/3/Problem Not Resolved)

/(EVT 42/

Delivery Blocked/2)

/(END

Delivery Blocked --------------------)

/(BEGIN

Misfeeds --------------------)

/(EVT 42/

Misfeeds/1)

/(EVT 42/

Misfeeds/3/

User Entered Text)

/(EVT 42/

Misfeeds/3/Problem Resolved)

/(EVT 42/

Misfeeds/3/Problem Not Resolved)

/(EVT 42/

Misfeeds/2)

/(END

Misfeeds --------------------)

/(BEGIN

Obstructed Product Flow --------------------)

/(EVT 42/

Obstructed Product Flow/1)

/(EVT 42/

Obstructed Product Flow/3/

User Entered Text)

/(EVT 42/

Obstructed Product Flow/3/Problem Resolved)

/(EVT 42/

Obstructed Product Flow/3/Problem Not Resolved)

/(EVT 42/

Obstructed Product Flow/2)

/(END

Obstructed Product Flow --------------------)

/(BEGIN

Sensor Blocked --------------------)

/(EVT 42/

Sensor Blocked/1)

/(EVT 42/

Sensor Blocked/3/

User Entered Text)

/(EVT 42/

Sensor Blocked/3/Problem Resolved)

/(EVT 42/

Sensor Blocked/3/Problem Not Resolved)

/(EVT 42/

Sensor Blocked/2)

/(END

Sensor Blocked --------------------)

/(BEGIN

User Entered Breakdown --------------------)

/(EVT 42/

User Entered Breakdown/1)

/(EVT 42/

User Entered Breakdown/3/

User Entered Text)

/(EVT 42/

User Entered Breakdown/3/Problem Resolved)

/(EVT 42/

User Entered Breakdown/3/Problem Not Resolved)

/(EVT 42/

User Entered Breakdown/2)

/(END

User Entered Breakdown --------------------)

N9999 M30

%

Legend for The OEE-Breakdown RRC Template Above

- Red:

- Green:

- The only Text allowed to be changed by an Operator.

- Gray: "/"

- The Only Character allowed to be deleted and added back

at the beginning of a Comment Line! Explanation to follow!

- /(BEGIN Event ---------) & /(END Event ---------):

- Encapsulates one OEE-Breakdown Event

General Operating Procedure

Using OEE Templates to Output OEE Data

Selecting the OEE-Breakdown Template (Selecting your OEE Monitoring Programs)

General Procedure for outputting OEE Data!

The general procedure for using the RRC Template to output OEE Data is to choose ONE of the Events that best describes the Present Event such as Equipment Failure.

None of the other Events in the RRC Template should be modified until the User has finished using this Event.

There is a minimum of two Processes that need to be completed to have a valid Event. As a minimum there must be a Start(Activating) and eventually an

End(Deactivating) for a complete Event Cycle.

This in just enough to record a valid Event but without any Event details. To enhance this Event there needs to be at least

one Event that happens in between the Start and End Event.

ShopFloorMonitoring provides at least two Events in between the Start and End Events. One of the Events has a Text Area that is User modifiable and is

marked as User Entered Text or equivalent. The other Event has a standard Reason or Comment that shouldn't be changed.

For each individual Event (Start, Comment, End, etc.) to be activated requires a minimum of removing the Character "/" from the beginning of the Comment line

of the selected Event and then uploading the WHOLE file!

ShopFloorMonitoring only process lines that have the Character "/" removed from the beginning of the Comment Line. After uploading you need to add the Character "/" back

in front of the Comment Line! You should never have more the ONE "/" Character removed from the Original RRC Template when uploading. These two requirements are Important!

When selecting an Event that is in between the Start & End Events not only will you need to Remove the Character "/" but you may also want to modify the User Entered

Text before uploading the WHOLE File!

The OEE-Breakdown Event: Equipment Failure

/(BEGIN Equipment Failure --------------------)

/(EVT 42/Equipment Failure/1)

/(EVT 42/Equipment Failure/3/User Entered Text)

/(EVT 42/Equipment Failure/3/Problem Resolved)

/(EVT 42/Equipment Failure/3/Problem Not Resolved)

/(EVT 42/Equipment Failure/2)

/(END Equipment Failure --------------------)

An Example using the Equipment Failure RRC Template!

STEP 1 (Start)

/(BEGIN Equipment Failure --------------------)

(EVT 42/Equipment Failure/1)

/(EVT 42/Equipment Failure/3/User Entered Text)

/(EVT 42/Equipment Failure/3/Problem Resolved)

/(EVT 42/Equipment Failure/3/Problem Not Resolved)

/(EVT 42/Equipment Failure/2)

/(END Equipment Failure --------------------)

UPLOAD

STEP 2 (Comment)

/(BEGIN Equipment Failure --------------------)

/(EVT 42/Equipment Failure/1)

(EVT 42/Equipment Failure/3/Spindle Bearing Bad)

/(EVT 42/Equipment Failure/3/Problem Resolved)

/(EVT 42/Equipment Failure/3/Problem Not Resolved)

/(EVT 42/Equipment Failure/2)

/(END Equipment Failure --------------------)

UPLOAD

STEP 3 (End)

/(BEGIN Equipment Failure --------------------)

/(EVT 42/Equipment Failure/1)

/(EVT 42/Equipment Failure/3/Spindle Bearing Bad)

/(EVT 42/Equipment Failure/3/Problem Resolved)

/(EVT 42/Equipment Failure/3/Problem Not Resolved)

(EVT 42/Equipment Failure/2)

/(END Equipment Failure --------------------)

UPLOAD

STEP 4 (Restore to the unaltered Event)

/(BEGIN Equipment Failure --------------------)

/(EVT 42/Equipment Failure/1)

/(EVT 42/Equipment Failure/3/User Entered Text)

/(EVT 42/Equipment Failure/3/Problem Resolved)

/(EVT 42/Equipment Failure/3/Problem Not Resolved)

/(EVT 42/Equipment Failure/2)

/(END Equipment Failure --------------------)

Note: You can find more information in the other Sub-Websites and our User Manual!